Customer On-Site Training

Military Standards

Rapid Mat US, Inc can develop and can provide training programs covering all areas of Rapid Runway Repair, to include deployment, employment, and maintenance of the hinged Folded Fiberglass Mats and supporting components and equipment.

All training programs are realistic and provide hands-on practical exercises. Instructors are former senior U.S. Air Force personnel with extensive, specialized Rapid Runway Repair training and experience. Trainees are tested on a "GO / NO-GO" basis to ensure the trainee's ability to perform the stated mission essential tasks (MET) associated with each respective course.

To develop the customized training program, Rapid Mat US, Inc curriculum developers conduct a site visit assessment of the customer's Air Bases and schedule coordination meetings with the customer. The training is customized based on the assessment of the customer's current capabilities, knowledge of Rapid Runway Repair, future requirements, and the specific desires and expectations of the customer. The length of each training course is adjusted accordingly.

For foreign customers, Rapid Mat US, Inc translates all training material into the customer's language, and has a certified translator present during all training to provide verbal translation of each course.

Site Deployment Services

-

Rapid Mat US, Inc handles shipping (overseas and domestic) of all RRR items and support equipment, as well as forwarding of the items to the customer's selected Air Base(s) location. During the first Program Management Review (PMR), Rapid Mat US, Inc personnel perform route reconnaissance to determine the best deployment methods and routes to the identified Air Base(s). The customer provides assistance and facilitates customs clearance for the materials associated with the RRR Systems.

For operational Heavy Lift Equipment and Heavy Lift Support Vehicles, Rapid Mat US, Inc manages the procurement of the Operational and Training heavy lift equipment and support vehicles, as required, from each item's respective location of manufacture or procurement to the respective customer Air Base(s) location.

Air Base Capabilities Assessment

Value-Added

-

As a Value-Added service, Rapid Mat US, Inc can provide a Capabilities Assessment that includes identification and determination of the customer's RRR requirements. The Capabilities Assessment identifies the runway composition (to ensure correct anchoring of the FFMs); vehicle, equipment, and heavy equipment requirements; RRR pesonnel requirements; current (or required) Emergency Management Plans / Function & Activity Preparation tasks; communications capabilities; levels of RRR Training accomplished or required; and spare parts requirements. Rapid Mat US, Inc surveys the heavy equipment available in the customer's current inventory to determine if this equipment can be integrated with the new systems.

Training Programs

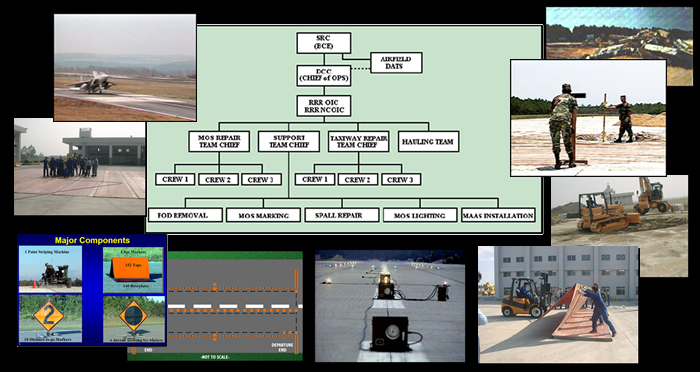

- RRR Concept of Operations

- RRR equipment requirements

- Development of a typical RRR Organization

- Pre-attack Procedures

- Trans-attack Actions

- Post-Attack Procedures

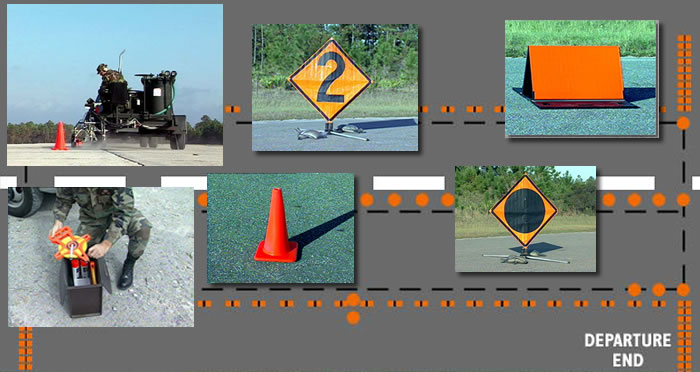

- Minimum Operating Strip (MOS) Marking System

- MOS Concept of Operations

- MOS Cone, threshold/Edge Marker, Aircraft Arresting Gear Distance-to-Go Marker Layout

- MOS access Taxiway Marking Procedures

- Crater Profile Measurement

- CPM Concept of Operations

- CPM Procedures

- Crush Stone Crater Repair

- Definition of Crush Stone Repair

- Repair Team Personnel, Equipment

- Crush Stone Crater Repair Procedures

- Crush Stone Repair Variations and Uses

- Maintenance of RRR Repairs

- Spall Repair

- Definition of a Spall

- Spall Repair Materials and Protective Equipment

- Spall Preparation

- Spall Repair Procedures for Magnesium Phosphate/Mortar

- Spall Repair Procedures for Asphalt

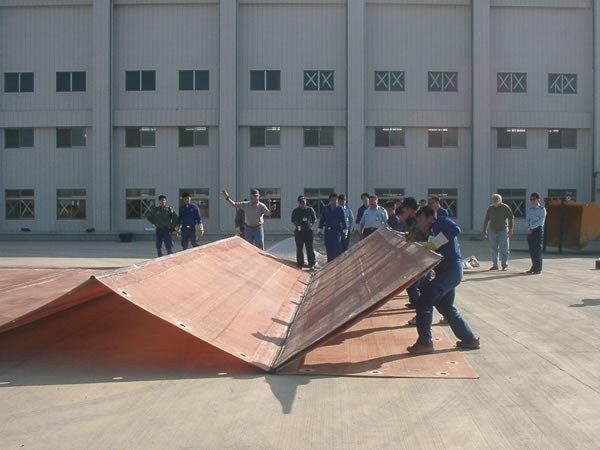

- Folded Fiberglass Mat Operations

- General Information

- Storage/Inspection of System Components

- Movement/Delivery of Mats

- Unfolding Mat Assembly

- Splicing/Joining Mat Assembly

- Towing Mat Assembly

- Anchoring Mat Assembly

- Mat Repair and Maintenance

- Command & Control / Survival Recovery Center

- Base Recovery After Attack (BRAAT) Concept

- Typical BRAAT Activities

- Survival Recovery Center Operations

- Development of Base Recovery Strategies

- Command & Control / Damage Control

- Damage Control Center Operations

- Communications issues

- Handling Damage/Status Reports

- Tracking Resources

- Control and care of engineering repair crews

- Shift Change Briefings

- Emergency Airfield Lighting System (EALS)

- Review of MOS Marking System

- System Components Overview

- System Layout and Configuration

- Pre-installation Procedures

- Installation Procedures

- Operation Procedures

- Troubleshooting and Maintenance

- Repacking

- Checklists and Safety

TOPIC / COURSE CONTENTS |

TRAINING METHOD |

| RRR Concept of Operations

|

Classroom |

TOPIC / COURSE CONTENTS |

TRAINING METHOD |

| Minimum Operating Strip

|

Classroom followed by hands-on field training. Hands-on field training requires access to, and uninterrupted use of, a 10,000 foot runway for the entire field training course. |

TOPIC / COURSE CONTENTS |

TRAINING METHOD |

| Crater Profile Measurement

|

Classroom only, or Classroom followed by hands-on field training. Hands-on field training requires the creation of a crater at the customer's training site. |

TOPIC / COURSE CONTENTS |

TRAINING METHOD |

| Crush Stone Crater Repair

|

Classroom only, or Classroom followed by hands-on field training. Hands-on field training requires the creation of a crater at the customer's training site, availability of crush stone, and heavy support equipment. |

TOPIC / COURSE CONTENTS |

TRAINING METHOD |

| Spall Repair

|

Classroom only, or Classroom followed by hands-on field training. Hands-on field training requires the customer to have the applicable type of Spall Repair materials, equipment and tools available. This will be determined during the procurement phase. |

TOPIC / COURSE CONTENTS |

TRAINING METHOD |

| Folded Fiberglass Mat Operations

|

Classroom followed by hands-on field training. Hands-on field training requires access to, and uninterrupted use of, a 10,000 foot runway for the entire field training course; availability of heavy support equipment. |

TOPIC / COURSE CONTENTS |

TRAINING METHOD |

| Command & Control Survival Recovery Center |

Classroom  |

TOPIC / COURSE CONTENTS |

TRAINING METHOD |

| Command & Control Damage Control |

Classroom  |

TOPIC / COURSE CONTENTS |

TRAINING METHOD |

| Emergency Airfield Lighting System (EALS)

|

Classroom followed by hands-on field training. Hands-on field training requires access to, and uninterrupted use of, a 10,000 foot runway; availability of EALS support vehicles. |

Extended Services

Logistics / Maintenance Support Plan

Logistics / Maintenance Support Plan  Multi-Year Maintenance and Support after delivery

Multi-Year Maintenance and Support after delivery